| |

| Pressure Action

Pumps |

| |

|

Pressure power pumps have been

part of our steam heritage since the early 1900's. Are you tired of paying

fulltime crews to repair or replace the same Electro-mechanical pumps over and

over?

Tunstall Pressure Action Pumps are the maintenance free

solution for peace of mind and long term savings. |

|

Tunstall AP-400 Series

Pressure Action Pump

The Tunstall AP-400 Series Pressure Action

Pump is the low maintenance, non-electric solution to move condensate or other

liquids from low points, low pressures or vacuum spaces to an area of higher

elevation or pressure. Condensate can be returned at temperatures well above

the 210° F limit of conventional problems.

| Features: |

| - |

Non-electric - utilizes inexpensive steam, air or gas to

operate the action pump |

| - |

Explosion Proof - Intrinsically safe |

| - |

Low Maintenance - No leaking seals, impeller or motor

problems |

| - |

All stainless steel internals |

| - |

Externally removable/replaceable seats - valve & seats

can be replaced or cleaned without removing pump cap from body |

|

| |

| Table 1-1 Series

AP-400 Pressure Action Pump - Piping Dimensions |

| Model Number |

AP-404 |

AP-406 |

AP-408 |

AP-412 |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

| Inlet Connection |

1 |

25 |

1½ |

40 |

2 |

50 |

3 |

80 |

| Outlet Connection |

1 |

25 |

1½ |

40 |

2 |

50 |

2 |

50 |

| Motive Pressure Connection |

½ |

15 |

½ |

15 |

½ |

15 |

½ |

15 |

| Vent Connection |

1 |

25 |

1 |

25 |

1 |

25 |

1 |

25 |

| Gauge Glass Connection |

½ |

15 |

½ |

15 |

½ |

15 |

½ |

15 |

|

| |

| Table 2-1 Series

AP-400 Pressure Action Pump - List of Materials |

| Name of Part |

Description |

| Cap, Body and Bolting |

Fabricated Steel 150 psi ASME Sec. VIII

Design "U" Stamp

Coded. |

| Cap Gasket |

Compressed Non-Asbestos |

| Inlet Valve Assembly |

Stainless Steel |

| Vent Valve Assembly |

Stainless Steel |

| Valve Assembly Washers |

Zinc-Plated Steel |

| Plug |

Steel |

Mechanism Assembly:

Float and Springs |

Stainless Steel |

*Series AP-400 available in all stainless

steel. Consult Factory. |

| |

| Table 4-1 Inlet

Reservoir Pipe Sizing For Closed Systems |

Condensate

Load

lbs/hr |

Reservoir Pipe Diameter (in) |

| 2" |

3" |

4" |

6" |

8" |

10" |

| up to |

Length of Pipe (feet) |

| 1000 |

4½ |

2 |

1½ |

|

|

|

| 1500 |

7 |

3 |

2 |

|

|

|

| 2000 |

9 |

4 |

2½ |

|

|

|

| 3000 |

13½ |

6 |

3½ |

2 |

|

|

| 4000 |

18 |

8½ |

5 |

2½ |

|

|

| 5000 |

|

10 |

6 |

3 |

1½ |

|

| 6000 |

|

12 |

7 |

3½ |

2 |

|

| 7000 |

|

14½ |

8½ |

4 |

2 |

|

| 8000 |

|

16½ |

9½ |

4½ |

2½ |

1½ |

| 9000 |

|

|

11 |

5 |

3 |

2 |

| 10000 |

|

|

12 |

5½ |

3 |

2 |

| 11000 |

|

|

13 |

6 |

3½ |

2 |

| 12000 |

|

|

14 |

6½ |

4 |

2½ |

Note: Inlet reservoir pipe sizing. When

draining condensate from a single piece of equipment in a "closed

system" to achieve maximum energy efficiency (see Fig. 2-2), a reservoir

should be installed horizontally above and ahead of the action pump. Sufficient

reservoir volume is required above the filling head level to hold condensate

during the action pump discharge cycle. The chart above shows the minimum

reservoir sizing, based on the condensate load to prevent equipment flooding

during the action pump discharge cycle. |

| |

| Table 4-2 Vented

Receiver Sizing for an "open system" |

| *Flash Steamlbs/hr |

|

Receiver

Diameter |

|

Receiver

Length |

|

Vent Line

Diameter |

|

| up to |

|

|

|

|

|

|

|

| 75 |

|

4" |

|

|

|

1½" |

|

| 150 |

|

6" |

|

|

|

2" |

|

| 300 |

|

8" |

|

36" |

|

2½" |

|

| 600 |

|

10" |

|

|

|

3" |

|

| 900 |

|

12" |

|

|

|

4" |

|

| 1200 |

|

16" |

|

|

|

6" |

|

| 2000 |

|

20" |

|

|

|

8" |

|

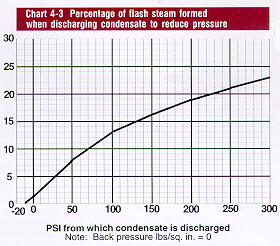

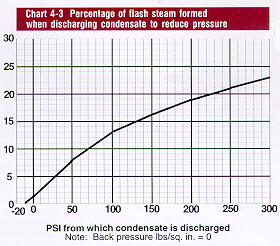

Important Note: Vented Receiver Sizing. When

draining from single or multiple pieces of equipment in a "open system",

a vented receiver should be installed horizontally above and ahead of the

action pump (See Fig. 2-1). In addition to sufficient holding volume of the

condensate above the fill head of the action pump to hold the condensate during

the action pump cycle, the receiver must also be sized to allow

enough area for flash steam and condensate seperation. An overflow could also

be added when required. The minimum recommended water seal is 12". The chart

above shows proper receiver tank sizing based on flash steam present. See chart

4-3 to calculate the % of flash steam at a given pressure drop. |

| |

|

| |

Suggested

Specification

|

The non-electric condensate pump shall be

Tunstall International AP-400 series operated by steam, compressed air or other

pressurized gas up to 125 psig. Electricity, seals or packings shall not be

used.

AP-400 series body construction shall be of carbon steel and

vessel shall be ASME Section VIII "U" stamp coded.

Pump internals shall

consist of all stainless steel float operated mechanical mechanisms. Motive and

vent valve/seats shall be externally removable without removing cap from the

vessel body for ease of maintenance and inspection. |

|

| |

|

Home - Capsules -

Cross References - Savings - Thermostatic Traps

F&T Traps - F&T

Kits - Action Pumps -Bucket Traps - TD

Traps |

| |

|